Building bricks are as old as man’s desire to stop moving! Of course, this makes perfect sense-after food, what mattered more than shelter? And from this basic instinct to survive, an eleven-thousand-year-old tradition was born.

Basic Beginnings and Early Improvements

Archaeologists can date back the earliest known bricks to about 9000 BC. These were hand-molded from basic mud and dried by air and sun. While it was a start, these first samples were not built to last. Over time, three key advancements were made:

- First, it was discovered that mineral-rich clay, common to river banks, was a superior component than plain mud. The minerals formed a stronger bond and resulted in a more durable finished product.

- Next, the development of molds was a great improvement over hand-shaped building bricks. This allowed for uniformity, and therefore more efficient, well-built structures.

- Lastly, between 4000 and 3500 BC, the practice of baking bricks in fired kilns was introduced.

This last innovation, achieved in the world’s first civilization, Mesopotamia, (in modern day Iraq) revolutionized building techniques, and enabled the completion of structures on a massive scale. Building bricks were now significantly more durable and highly resistant to water damage.

Around the ancient world, the civilizations that followed continued to improve brickmaking methods:

- By 3000 BC, the Chinese had introduced the Clamp Kiln, which allowed for higher temperatures and produced bricks in greater quantities.

- The Chinese also experimented with different clay compositions and additives. This improved brick quality and structure for various environments, which proved beneficial for the wildly extensive Great Wall. It’s estimated that there are over 3 BILLION bricks used in it!

- By 2500 BC, the Egyptians were using specialized molds which gave them uniformity, and added straw to create more lasting building bricks used in some of their smaller pyramids, temples, homes and tombs.

The Roman Effect: Innovation and Expansion

As they did with many things, the Romans likely used what they learned about building bricks from the areas they conquered and combined them with their own engineering prowess. The results were significant:

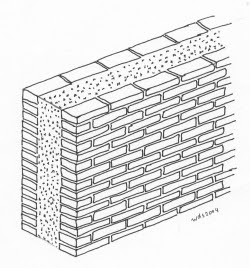

- Opus Latericium-a building technique where a cement core is faced and reinforced by layers of bricks on each side.

- The Voissured Arch-The Romans featured arches in much of their construction, recognizing their ability to bear heavy weights. The voussoirs were wedge-shaped building bricks molded to fit the contours of the arch.

- Mobile kilns-true to their nature, the Romans developed kilns that met their goals of expansion. Their ambitious plans meant the need for millions of bricks. Making and transporting them made no sense when they could bring the kiln and use local materials.

The Romans brought the use of building bricks to much of Europe. In areas where suitable stone was scarce, they became a versatile, cost-effective alternative. This was especially true in northern and central Europe, where Gothic brick architecture emerged in the late Middle Ages.

And by the Renaissance, brick had taken its place alongside stone in some of the architectural masterpieces of the era, such as Florence’s El Duomo, Milan’s Castello Sforzesco, and Germany’s Reinbek Castle.

By the Industrial Revolution, bricks were being mass-produced on an unprecedented scale. Steam powered mechanical presses and massive kilns made building bricks a foundation of urban development and industrial expansion. They were now essential to keeping up with the needs of rapidly changing society.

And so thousands of years later, modest building bricks were still serving the same purposes they did in the beginning for the people who made them: providing shelter, representing permanence, and contributing to the advancement of civilization as a whole.

At Stone Farm, we celebrate the permanence of building bricks by reclaiming them from buildings and factories that are being torn down. We keep the stories of these bricks alive, by slicing them to use as Thin Brick Veneer and Brick Floor Tile, so people can have a part of this history in their homes and businesses. There is nothing like the beauty of authentic reclaimed brick to imbue a project with a historic feel.

Look at what’s next in our History of Brick Series: The Thin Brick Veneer Revolution Learn how people’s love of brick inspired a new an easier way to achieve the look without the structure.